The Role of Partial Oxidation Units in Hydrogen Production

Hydrogen offers a high-energy, zero-emission fuel for various applications, from powering cars to heating homes. Among the several methods available for hydrogen production, partial oxidation (POX) stands out, particularly for its efficiency in processing a variety of hydrocarbon feedstocks.

What is Partial Oxidation?

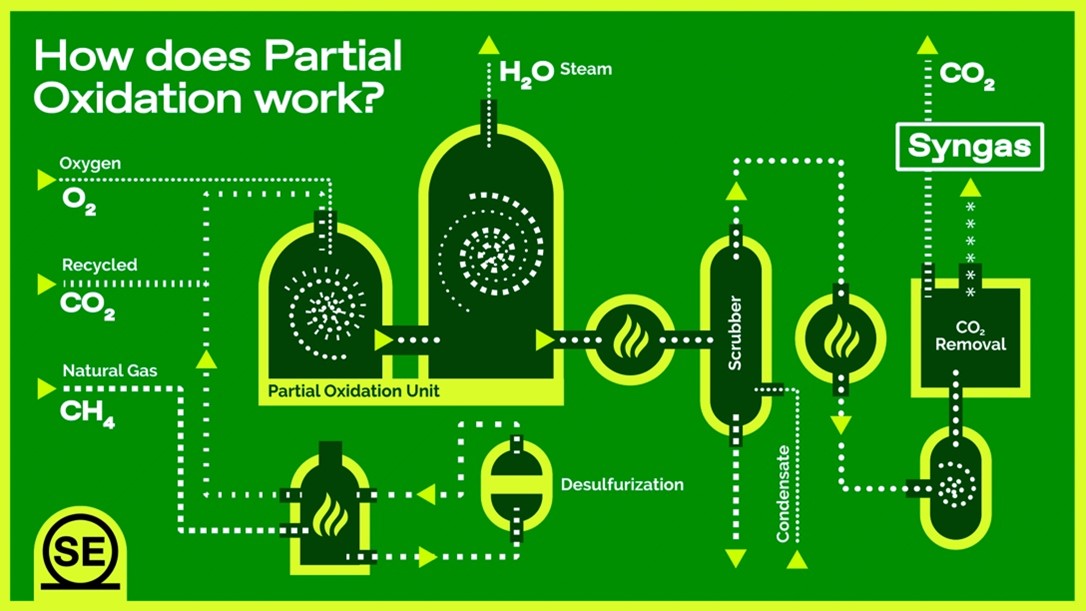

Partial oxidation (POX) is a process whereby hydrocarbons are converted into hydrogen and carbon monoxide by oxidation at elevated temperatures. This reaction occurs in the presence of a controlled amount of oxygen, less than what is needed for complete combustion. The resultant synthesis gas (syngas), primarily composed of hydrogen and carbon monoxide, can then be further processed to increase hydrogen yield or used in various chemical syntheses.

The Advantages of Partial Oxidation Units

- Versatility with Feedstocks: POX units are not picky about their feed. They can process a wide range of hydrocarbons, including heavy oils and renewable feedstocks that are challenging to utilize in other reaction processes like steam methane reforming (SMR).

- High Efficiency: By optimizing the oxygen-to-hydrocarbon ratio, POX units can achieve high conversion efficiencies. This makes them particularly valuable in settings where maximizing the output from available resources is crucial.

- No Catalyst: Since the POX does not utilize any catalyst, this eliminates the need for feed pretreatment, as long as the product requirements are met.

- Cost-Effectiveness: While the initial capital investment for a POX unit might be significant, the ability to use different feedstocks can lead to lower operational costs compared to processes requiring purer feedstocks.

- Integration with Carbon Capture: The high-pressure environment of POX reactors facilitates the integration of carbon capture technologies. This synergy can significantly reduce the carbon footprint of hydrogen production, aligning with global carbon reduction goals.

Challenges and Considerations of partial oxidation units

Despite their advantages, partial oxidation units are not without challenges. The high temperatures and pressures required for operation demand robust, high-grade materials and advanced engineering to ensure safety and durability. Additionally, the process’s nature means that careful management of emissions is necessary to prevent environmental impact.

As the demand for hydrogen continues to grow, spurred by increasing recognition of its role in a sustainable energy future, technologies like partial oxidation will become ever more critical. Innovations in reactor design, and integration with renewable energy sources could further enhance the efficiency and environmental compatibility of POX units.

At Samuel, our syngas and hydrogen team brings a broad range of expertise. With decades of experience, Samuel will maximize value and efficiency at every stage of your syngas project, including engineering, procurement, modular fabrication, and construction. Contact John Cotten (jcotten@samuelengineering.com) to learn more.