Infrastructure Security & Maintenance

The Systems Engineering group at Samuel Engineering, Inc. (SE) provides an all-encompassing solution for Clients’ critical infrastructure. Our team of IT Professionals have expertise in Enterprise Architecture, Data Center Technology, IT infrastructure and Network Security. We can provide services ranging from a specific project to a complete technology solution.

Core Capabilities

- Network Administration

- Storage Capacity Planning and Optimization

- Business Continuity and Disaster Recovery

- Systems Administration

- Release Management Performance Tuning

- Installation, Configuration and Management of Virtual Environments and Tools

- Identity and Access Management

automation capabilities

automation design

- Instrument & Control System Design Basis

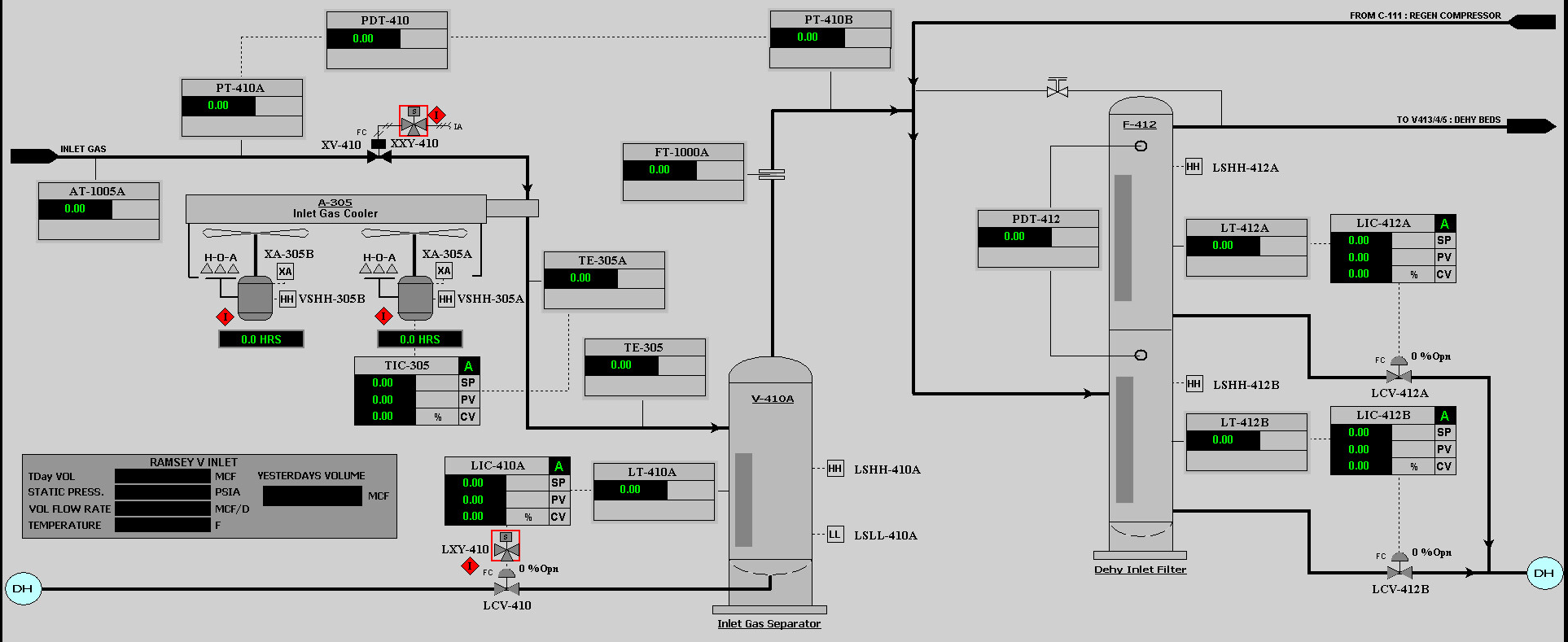

- P&ID Development

- DCS Architecture (BPCS & SIS)

- PLC / SCADA Architecture (BPCS & SIS)

- Network Architecture

- Control Panel Design

- Hardware / Software Specification

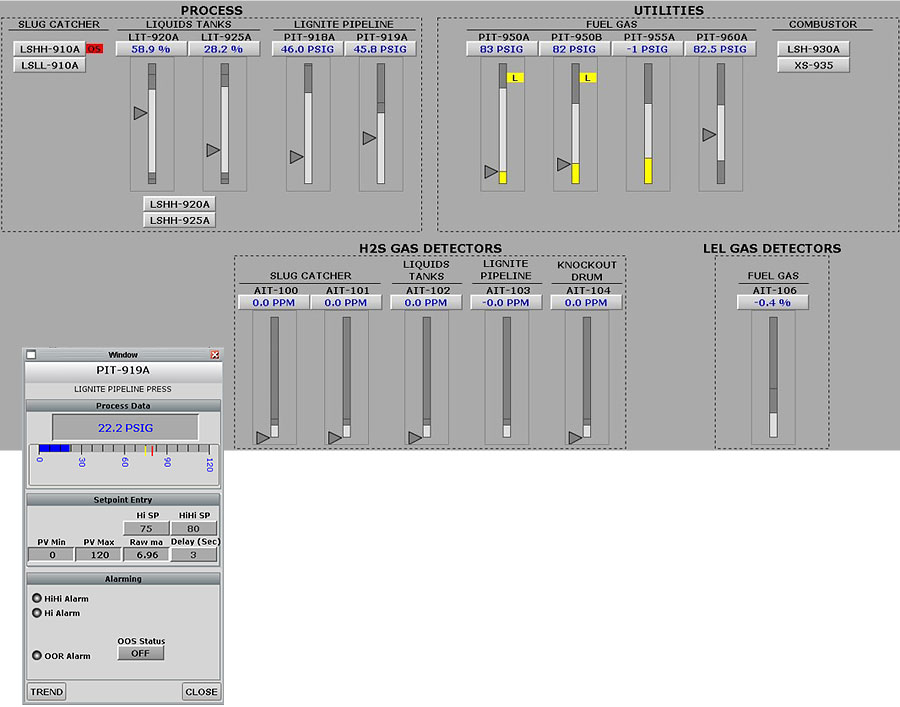

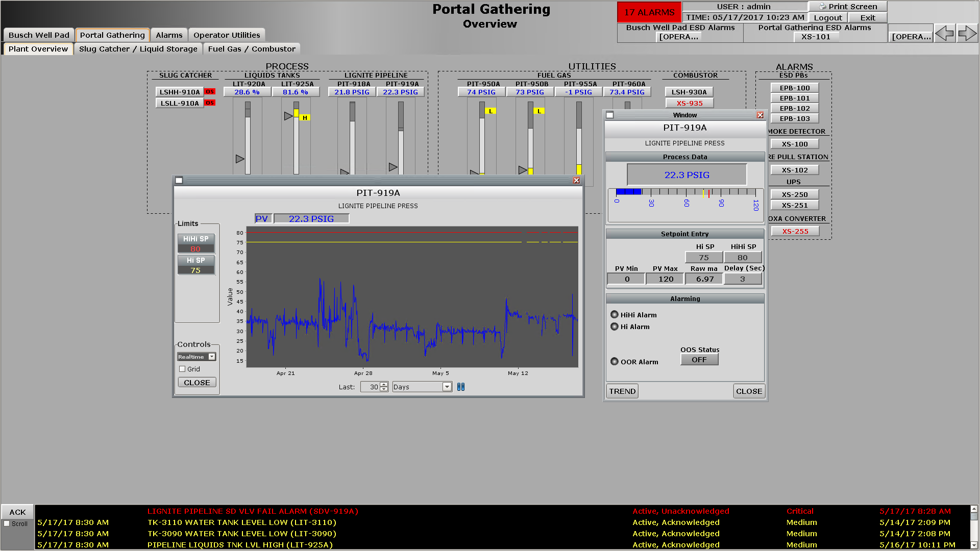

- HMI Development

automation deployment

- Plant Start-Up and Commissioning

- Commissioning Plans

- Calibration Sheets

- Loop Check Forms

- Vendor Acceptance

automation development / configuration

- Control System Philosophies

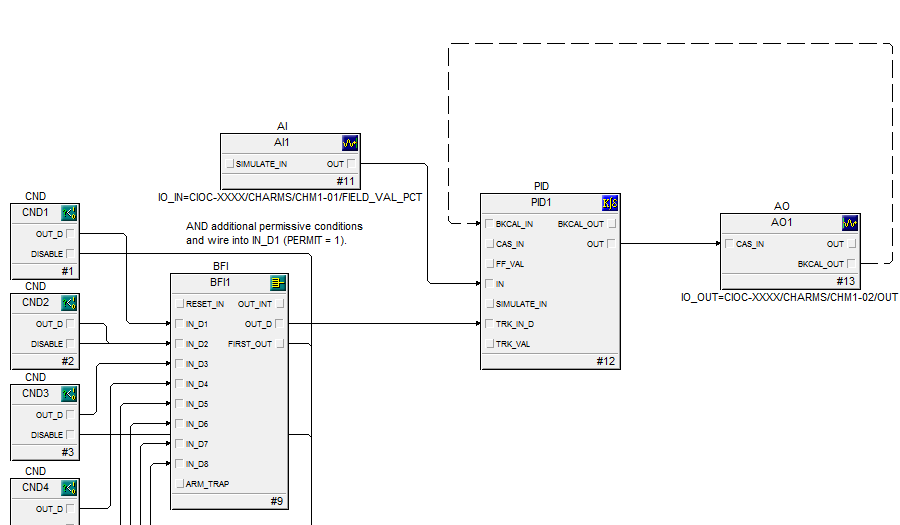

- DCS Software Strategies

- PLC / SCADA Software Strategies

- Virtualization

- Control Panels

- Edge Servers / Routers

- Smart MCC Design

- VFDs/Motors

- Switchgear

- Generators

- Instrument Data Sheets

- Instrument Indices

- I/O Lists

- Cause & Effect Matrices

- FAT (Factory Acceptance Testing)

- HAZOP (Hazard and Operability Study)

- LOPA (Layer of Protection Analysis)

- SIS (Safety Instrumented Systems)

- Software Acceptance Testing

new automation lab

SE launched a newly renovated and upgraded on-site Automation and Instrumentation laboratory at SE headquarters in Denver, CO. The original lab was opened in 2013 and has yielded considerable internal benefits including the intrigue of both our US based and international clients. Our new lab represents a significant upgrade in both size and technologies represented.

FUNCTIONS OF SE’S NEW AUTOMATION LABORATORY

- Testing, simulating, validating and demonstrating our solutions prior to deployment to the project site.

- Marketing and sales showcase. A variety of different technologies and brands will be on display and will allow our customers functional demonstrations as it pertains to their specific project.

- Conducting experiments and investigations.

- Facilitating employee collaboration and training.

- Mentoring, e.g. during engineering week and “take your child to work day”.

CONTENTS OF THE UPGRADED LAB

- Final control devices (level, flow, pressure, temperature devices, valves, etc.)

- Control devices and software (PLCs, DCS, SCADA, etc.)

- Monitoring and HMI systems (demonstrating plant graphics, P&ID controls, etc.)

- Power Switching Control devices (MCC, motor starters, VFD, etc.)

- Marshalling and Lighting controls

team MEMBER highlights

Kay Dhliwayo, Sr. Automation Engineer

Kay has been with Samuel Engineering for 13 years. He has 14 years of experience as an Automation / Controls & Instrumentation Engineer, and 5 years as an IT Professional in various roles.

Kay has conducted PLC / HMI programming on Mining projects and large Natural Gas projects using PLCs that include: Wonderware’s ArchestrA & InTouch, Intellution’s iFix, Allen-Bradley’s FactoryTalkViewm, Allen Bradley’s Logix Family of PLCs, Schneider Electric’s Quantum & Momentum PLCs, GE Fanuc’s RX7i, RX3i & 90-70 / 30 Series, ICL SCADA Controllers, ABB Flow Controllers, Bristol Babcock’s Control Wave PLCs. Kay has also worked with HMIs that include Studio, GE’s Proficy Machine Edition, Inductive Automation’s Ignition, Iconics’ Genesis 64 & Genesis 32, & Rosemount’s DeltaV & OpenEnterprise.

Mike Johnson, PE, Sr. Automation Engineer

Mike has been with Samuel Engineering for 11 years. He has forty-three years of Instrumentation and Automation Systems Engineering experience. Mike provides expertise in computer-based information and control systems; specifically, regarding the collection, qualification, storage, recall, and processing of information (real-time, archival, and decision/predictive support).

Mike has worked extensively on projects containing data telemetry, SCADA, DCS, PLC, control strategy development/implementation, local and distributed data communication networks, system response analysis, information management, and the migration of control systems from one operating platform to another.

CONTACT US

We want to hear from you. Please send us your questions, requests and comments.

Andraé Alexander

I&C Engineering Supervisor

Direct: 303.567.7622